Chuangzhou Chuanggan Microwave Drying Equipment Co.,Ltd.

Address:LiangZhuang Development Zone.Jiaoxi,Zhenglu Town,ChangZhou City,Jiangsu Province

General Manager:YuHongPing

Mobile:(0)13601527797 (0)15852586668

Tel:+86-519-88911118 +86-519-88911228

Fax:+86-519-88911558

Post code:213116

E-mail:y13601527797@126.com

sales@chuanghong-drying.com

Dry granulator is a kind of energy saving and environment-friendly new product developed by the company. It integrates the function of extrusion, crushing and granulating, and directly presses the powdery material into particles.

Summary:

Dry granulator is a kind of energy saving and environment-friendly new product developed by the company. It integrates the function of extrusion, crushing and granulating, and directly presses the powdery material into particles. This equipment uses a new roller pressure control technology to adjust the technological parameters of dry granulating, such as processing quantity, flake density, roller pressure, speed, etc., by adjusting the fluctuation of different materials and the physical properties of different batches of the same material, so as to produce high quality particles efficiently. It also improves the stability, disintegration and dissolution of the particles.

Dry granulator is widely used in pharmaceutical, food, chemical and other industries. It is especially suitable for granulation in wet, hot, easily decomposed and caking materials, and it has less area, simple process and easy disassembly and cleaning. In the pharmaceutical industry, granules made by dry granulators can be directly tableted or filled with capsules.

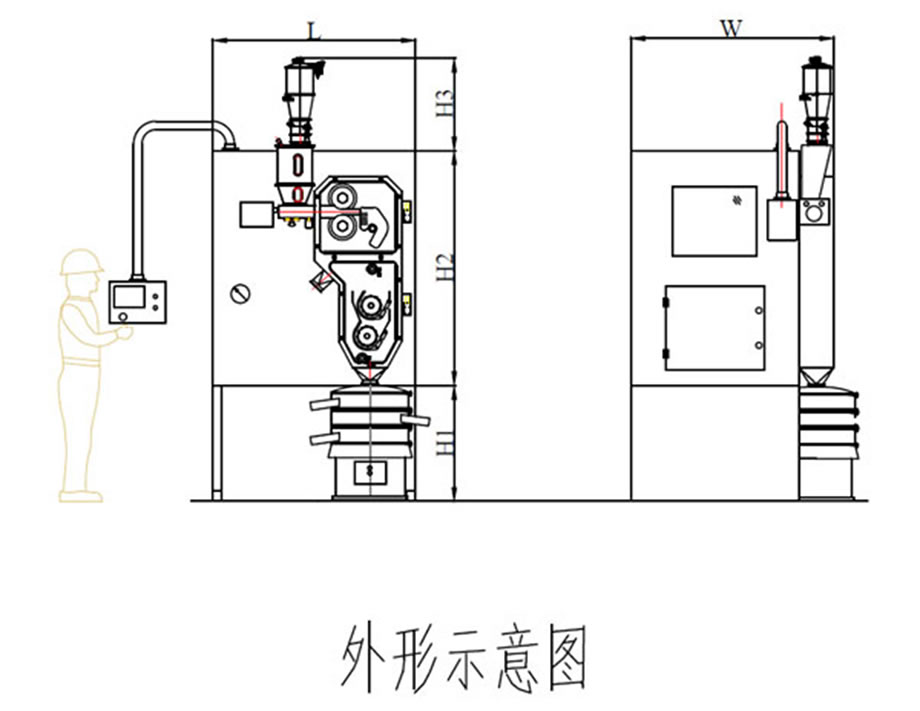

After mixing the powder material, the powder material is added into the silo by the top feeding port, and the mixed powder material is transported to the extruding device by the conveying mechanism. The material is pressed into the high density sheet through two high pressure extruding wheels, and then the particle of the required size is made through the two stage whole grain system, and the granulation process is completed.

Compared with the traditional wet granulating, dry particle particles make the powder raw materials directly into granular products without any intermediate and additives. The grain size is uniform and the accumulation density increases significantly after granulation, which not only controls the pollution, reduces the area of land, but also reduces the power consumption, the process flow is reasonable, and the material is improved. The material appearance and fluidity are easy to store and transport, and the solubility, porosity and specific surface area of the material can be controlled. It is especially suitable for wet mixed granulating and one step boiling granulation.

The specific performance is:

(1)The granulating device and the power device of the equipment are separated and installed in space to avoid cross-contamination;

(2)All parts in contact with materials are easy to be disassembled and cleaned, effectively preventing dust leakage and reducing the possibility of pollution;

(3)Unique stretching system makes material density uniform;

The unique air-cooling system makes the roller temperature automatically adjustable.

(4)Two-stage screening granulation system to ensure the production of granules to meet the requirements;

(5)Visibility design is adopted to facilitate observation and maintenance.

(6)Man-machine interface system, beautiful and easy to understand, easy to operate;

(7)Meet the requirements of GMP.